Timothy "TJ" Knob, Jr.

Sign up to be notified of our new blog posts.

How Precision Mixing Enhances Batch Consistency in Pharmaceutical Manufacturing

Learn how precision mixing technology can improve batch consistency in pharmaceutical manufacturing by ensuring even ingredient distribution and temperature control.

Six Tips for Food Manufacturers Purchasing Their First Mixing Vessel

For food manufacturers making the leap from small or shared-space production to expanded commercial production, processing equipment considerations can be overwhelming.

When Looking for a Vessel, Don’t Overlook the Value of a Professional Applications Engineer

In a world where you can buy anything you want from vendors you never meet in person, it’s easy to overlook the critical difference the right people—those real experts with real experience—can make on your success. This ideal is especially important for food, cosmetic, pharmaceutical, and other manufacturers looking for new processing vessels.

Annual Food Manufacturing Surveys Yield Important Equipment Considerations

We’re always paying attention to the issues our customers face in their businesses. That way, we can adapt our products and services to best fit their changing needs. So, the recent release of two annual research reports within the Food Manufacturing industry is particularly interesting.

Vacuum De-Aeration: Removing Trapped Air Bubbles for Uniform Product Consistency and Accurate Dosing

Manufacturers who process high-viscosity products such as creams, lotions, ointments or gels often encounter problems with air bubbles forming in the batch, as air becomes entrained in the product during agitation. These unwanted air bubbles can prevent exact measurement and dispensing of the product in its end-use packaging, a particular problem in bio-pharma products, where highly precise dosage amounts are often required for safe and effective patient treatment.

The Value of Custom-Built Processing Equipment…and What to Do If You Can’t Wait

Manufacturers that need processing equipment may have faced a similar challenge lately. While most would prefer equipment customized to their operation and product, some may feel they need to seek other options, like in-stock or used equipment. The long-term nature of processing equipment makes this a particularly important decision point: a high-quality production vessel can operate for decades.

Identifying Production Bottlenecks in Process Manufacturing Operations

If you’re involved in a process manufacturing operation, you likely spend a lot of time thinking about production bottlenecks. Perhaps, if your operation is one of the many currently struggling to keep pace with increasing demand, the issue has become a top priority for you to solve.

Pet Food Safety Incident Has Manufacturers Reviewing Their Operations

Pet food safety has been a hot topic in the industry since the 2011 enactment of the Food Safety Modernization Act (FSMA), which established stringent requirements for both human and pet food manufacturers.

Skincare Products: How to Make Sure You Get the Right Processing Equipment

Beauty may only go skin deep, but clearly, that’s enough to make today’s market for skincare products quite appealing.

Five Equipment Decisions that Affect Efficiency and Productivity

Expansion is on the minds of many process manufacturers lately. Driven by higher demand, product innovations and new distribution channels, processors are aggressively seeking to increase production in key industries like food, pharmaceutical, personal care and chemicals.

Challenge Accepted: Accommodating Low- and High-Viscosity Product in the Same Vessel

It’s one thing to engineer a processing vessel solution to optimize production for thick, high-viscosity product. But engineering a solution that works well for a product that starts as a water-like mixture and gradually takes on the consistency of heavy paste? That is an entirely different challenge.

The Tell-Tale Signs of Dimple Jacket Vessel Quality

Jacketed pressure vessels – in which a jacket that surrounds a production tank is used to circulate fluid to heat or cool the vessel’s contents – are deployed throughout the food, biopharma, cosmetic, chemical and lubrication industries. For manufacturers purchasing a jacketed vessel, one of the key decisions they must make concerns the jacket’s heat transfer style.

How 2021’s Key Food Industry Developments are Shaping Equipment Decisions

As the sun rises on a new year, food manufactures are seeing opportunities on the horizon. These opportunities, driven by fast-changing consumer behaviors and sentiments, foreshadow an exciting 2021, but may also force operational adjustments to accommodate higher demand and new product innovations. Many of these adjustments will entail decisions to add or modify processing equipment. Here are some of the key developments food manufacturers have on their plates, and the equipment ramifications they will be paying attention to:

Equipment Considerations for Plant-Based Food Processing

The plant-based food market is expected to expand at a compound annual growth rate (CAGR) of 11.9% from 2020 to 2027, and will reach $74.2 billion by 2027. As food manufacturers look to ramp up production of plant-based products, they must determine how to configure their processing equipment to effectively scale operations.

Factors That Determine the Best Agitator Design for Your Processing Operation

Processing operations involve a series of carefully engineered steps to produce, at scale, a finished product to its precise specifications. Clearly, operators that maximize the efficiency of their process and the consistency of their product gain a distinct financial advantage and more capacity to grow their business. A key contributor to accomplishing this is the operation’s processing equipment and the degree to which it is designed for the specific product and workflow.

Factors That Determine the Best Processing Vessel Design for Your Operation

Knowledgeable wine drinkers know that wine glasses are designed for specific types of wines, with characteristics like shape, size, even wall thickness purposefully engineered to bring out the best in a given varietal. The difference in taste from the right vs. wrong glass style can be remarkable. The same goes for processing vessels used in food, cosmetic or pharmaceutical operations, where effectively matching product traits and operational needs to equipment design can significantly impact performance. Learn more about vessel design options in our latest blog article.

Challenge Accepted: Preventing Burn-On When Cooking Cheese Sauce in a Jacketed Kettle

As anyone who has melted cheese on a stovetop knows, it is nearly impossible to keep it from sticking to the pot. And cleaning the inside surface afterward can be difficult. This was the challenge faced recently by one of our contract process and packaging customers. See how we solved this challenge in our latest blog article:

The CBD Product Market is Still Poised to Take Off, But Think About Operations Before You Jump On

Cowen & Co predicts the American CBD market could reach $16 billion by 2025. And that’s just for CBD. Should marijuana/THC become legal for at least three-fourths the population, Nielson projects an additional $34.8 billion! Sure, manufacturers are still working their way through uncertainty, particularly in food and beverage, where legal issues governing CBD’s use in consumables have yet to be resolved. But those seeking to capitalize would do well to think now about the unique production challenges of CBD and THC product manufacturing.

Sauce Manufacturing: Be Sure to Consider These When Choosing Your Processing Equipment

The sauce category within the food manufacturing industry is growing about 4.1% per year, spurring product innovation from both small and large processors. Processing vessel options can be as varied as the sauces themselves, with many design choices that will impact your product’s quality, consistency and production efficiency. To help you decide what’s best for your sauce processing operation, be sure to consider these factors:

Which lasting effects of the COVID-19 crisis will food manufacturers factor into 2021 planning?

The food industry is near the top of any list of those most directly affected by the coronavirus pandemic. The entire food supply chain -- from farming and processing to distribution and consumption -- has been disrupted, in many cases dramatically. Food manufacturers are sorting through this confusion to ensure they are well-positioned to operate effectively and take advantage of new opportunities. As they look ahead to 2021, several expected long-term effects will factor into their planning. See what to expect in our latest blog article:

Processing Equipment Options for Food Manufacturers to Meet Crisis Demand

Demand for many packaged food products is skyrocketing. Manufacturers are doing everything they can to keep up as they ramp production, while also enforcing heightened disinfection and social distancing directives. For some manufacturers, ramping production will necessitate stocking replacement valves and parts for processing equipment to ensure continuous operation, or even adding processing kettles or tanks to increase throughput. Here is an overview of options in-demand food manufacturers can consider:

A Key Nugget Buried in New Research Identifies How Food Manufacturers Plan to Increase Production

Each year Food Processing magazine conducts research to identify industry trends. At Lee Industries, this is always interesting to us as it highlights the issues on the minds of many of our customers. This year, however, the insight was particularly interesting...

Challenge Accepted: Faster Cooling in Jamaica

Sometimes, where you make a product will dictate how you make it. That was the case for a customer in Jamaica, a processor whose frozen food product contained ground meat. See how we helped this client meet the process time requirements in a very hot climate area.

Challenge Accepted: A Tight Fit

Maneuvering around the physical constraints of a plant is a common challenge for processors. But for one of our pharmaceutical manufacturing customers, a particularly difficult space problem required a particularly innovative solution. Challenge accepted.

Food Industry Growth Forcing Manufacturers to Rethink Processing Equipment

We’ve been a part of the food manufacturing world for over nine decades, so we know that change is a constant for the industry. But the pace of change today – and its impact on the food manufacturing process – is more significant than ever. Here are some of the key implications we see that will affect how food manufacturers make decisions on their processing equipment:

How to Make Sure the Kettle You Order is Actually the Kettle You Need

Much goes into building a high-performance processing vessel for a food, chemical or pharmaceutical manufacturing operation. Dozens of choices must be made about size, materials, mixing speeds, type of agitation, temperature, port locations, surface finishes and more. And each choice has an impact on how effectively the vessel performs in your environment. This blog article will guide your vessel design decision making and make sure you ask your process engineer the right questions.

5 Vessel Design Requirements for Optimizing Food Grade, Specialty and High-Performance Lubricant Manufacturing

Food-grade, specialty and high-performance lubricants, can pose mixing, temperature and safety challenges that require specialized vessel features and performance. To meet these processing challenges, manufacturers may be wise to emphasize five key characteristics in their processing vessels for optimal results. See the five key characteristics in our latest blog article.

Improving FSMA Compliance with Safety Features

Food safety is the top concern for food manufacturers this year, in no small part because of the FSMA. In Food Processing magazine’s annual industry survey, 27% of respondents identified food safety improvements as their top priority for this year. What components will these manufacturers scrutinize? Here are three areas where changes to manufacturing equipment can improve FSMA compliance.

Three Vessel Design Enhancements to Improve Your Throughput

Faster batch processing is a common goal for food processors. It’s often the impetus for adding more processing equipment. But improving throughput can involve much more than simply adding capacity. Depending on your objectives, optimizing your vessel design can dramatically reduce your batch processing time while also improving safety, product quality and product consistency. Here are three areas where optimizing your processing vessel can produce significant results.

Steam or Hot Water? Which Heating Source is Best for Your Operation?

Choosing a heat source is a key consideration for all food processing operations. For processors who use a jacketed kettle design, the choice comes down to steam versus hot water. But is one of them superior? And when would you choose to use one heat source over the other? Let’s consider some of the advantages of both steam and hot water while taking a look at some potential applications.

Why Surface Finish Grades are a Key Part of Your Production Vessel

The surface finish grade is a crucial but perhaps overlooked component of your production vessel. The surface finish affects more than the look of your vessel; it’s also critically important to how your vessel accomplishes its intended task — or whether it’s able to at all. A vessel’s surface finish will determine what products can be produced within that vessel. From pharmaceuticals to chemicals to food products, each industry has surface finish standards that must be met. And even beyond industry requirements, a vessel’s surface grade can have a big effect on how your product is produced.

The Importance of a Clear Manufacturing Quote for Your New Processing Vessel

Obtaining a proposal for equipment you intend to use in your processing operation is a critical part of your purchase process. Here are three key benefits of a clear, easy-to-understand manufacturing equipment quote.

Three Questions You Should Ask Your Processing Equipment Manufacturer

Preparing to buy a new piece of processing equipment can be a daunting process, but it doesn’t have to be. Knowing the right questions to ask before you buy can put you on the path to success.

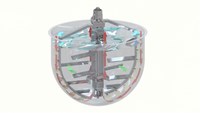

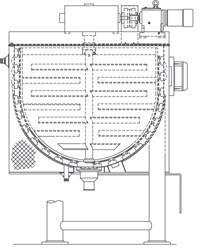

Three Ways Inclined Agitation Improves Operational Efficiency

Choosing the right kettle design is a key part of your food processing operation. When it comes to optimizing your production, there are two clear alternatives in the mixing and agitation area: horizontal ribbon blenders and hemispherical kettles with inclined agitation.

Five Questions to Ask When Buying a Used Kettle

Buying a used processing kettle can be a great option for expanding your operation or replacing older equipment. Used kettles and other vessels can often be available more quickly for lower prices than you’d see if you were buying new. But after weighing availability, price and basic design factors like shape, capacity and agitator type, there are other things you should weigh when deciding whether or not to buy a used kettle.

How to Improve Food Safety in Your Plant Operations

Assuring that your product will always be sanitary and free of contaminants is a critical food processing goal. So, when you are planning the design and configuration of your next kettle purchase, it is important to keep food safety in mind.

How to Improve Operator Safety in Your Food Processing Operations

During food processing, the safety of your production team is key. This article features key safety issues to consider in your food processing operation.