Equipment Design

Sign up to be notified of our new blog posts.

Six Tips for Food Manufacturers Purchasing Their First Mixing Vessel

For food manufacturers making the leap from small or shared-space production to expanded commercial production, processing equipment considerations can be overwhelming.

Vacuum De-Aeration: Removing Trapped Air Bubbles for Uniform Product Consistency and Accurate Dosing

Manufacturers who process high-viscosity products such as creams, lotions, ointments or gels often encounter problems with air bubbles forming in the batch, as air becomes entrained in the product during agitation. These unwanted air bubbles can prevent exact measurement and dispensing of the product in its end-use packaging, a particular problem in bio-pharma products, where highly precise dosage amounts are often required for safe and effective patient treatment.

When Food Manufacturers Must Choose Between In-House or Contract Manufacturing

Most food producers—at some point in their product’s lifecycle—arrive at a fork-in-the-road moment where they must decide to make their product in-house or outsource production to a contract manufacturer. Whether that moment occurs at the onset of a commercialization opportunity, once demand exceeds in-house capacity or when the economics reach a trigger point, determining the right production strategy can be complicated.

Skincare Products: How to Make Sure You Get the Right Processing Equipment

Beauty may only go skin deep, but clearly, that’s enough to make today’s market for skincare products quite appealing.

Five Equipment Decisions that Affect Efficiency and Productivity

Expansion is on the minds of many process manufacturers lately. Driven by higher demand, product innovations and new distribution channels, processors are aggressively seeking to increase production in key industries like food, pharmaceutical, personal care and chemicals.

Soup’s On: What to Consider When Adding Capacity for Soup Production

With a nod to a famous advertising tagline, more and more people around the world are agreeing that “soup is good food”. Even without the spike in demand caused by the pandemic in 2020, the global soup market was on a steady rise. So, it’s no surprise that researchers expect significant growth in the coming years, with global annual value reaching $20B by 2026 – a nearly 20% increase over 2020. This positive outlook – driven by a growing demand for healthy convenience food, mounting interest in global and ethnic culinary offerings and heightened popularity of fresh prepared/ready-to-eat and frozen foods – is leading many soup producers to evaluate their processing operations, to make sure they can consistently churn out enough product to meet demand.

Where the Vessel is Always Greener: the Environmental Impact of Lee Products

Like many companies, Lee Industries has been examining its environmental footprint. We wanted to think harder about how the products we manufacture fit in a “greener” world. Because we believe it is important that our equipment operates in an ecologically friendly manner, we continually seek ways to engineer our kettles and tanks to minimize their impact on our environment. Here are some of the methods we use to support that goal:

The Tell-Tale Signs of Dimple Jacket Vessel Quality

Jacketed pressure vessels – in which a jacket that surrounds a production tank is used to circulate fluid to heat or cool the vessel’s contents – are deployed throughout the food, biopharma, cosmetic, chemical and lubrication industries. For manufacturers purchasing a jacketed vessel, one of the key decisions they must make concerns the jacket’s heat transfer style.

9 Vessel Design Factors that Dramatically Affect CIP Performance

Lee Industries was one of the first vessel manufacturers to introduce CIP capabilities. Since then, we’ve learned a lot about optimizing vessel design to maximize sanitary performance and operating efficiency. Here are several best practices to help you design the best CIP-ready vessel for your operation.

Factors That Determine the Best Agitator Design for Your Processing Operation

Processing operations involve a series of carefully engineered steps to produce, at scale, a finished product to its precise specifications. Clearly, operators that maximize the efficiency of their process and the consistency of their product gain a distinct financial advantage and more capacity to grow their business. A key contributor to accomplishing this is the operation’s processing equipment and the degree to which it is designed for the specific product and workflow.

Jams, Jellies and Preserves: How to Choose the Right Processing Vessel

As consumers focus on healthy lifestyles and opt for natural products, demand for jam, jelly, and preserve products is growing. This growth, and the arrival of products featuring less sugar and the use of a wider range of spices, herbs and rare or exotic fruits, is leading some manufacturers to consider modifying, upgrading or adding processing equipment to keep pace. Ultimately, their equipment choices can have a significant effect on their overall operational performance. Learn more in our latest blog article:

Factors That Determine the Best Processing Vessel Design for Your Operation

Knowledgeable wine drinkers know that wine glasses are designed for specific types of wines, with characteristics like shape, size, even wall thickness purposefully engineered to bring out the best in a given varietal. The difference in taste from the right vs. wrong glass style can be remarkable. The same goes for processing vessels used in food, cosmetic or pharmaceutical operations, where effectively matching product traits and operational needs to equipment design can significantly impact performance. Learn more about vessel design options in our latest blog article.

Sauce Manufacturing: Be Sure to Consider These When Choosing Your Processing Equipment

The sauce category within the food manufacturing industry is growing about 4.1% per year, spurring product innovation from both small and large processors. Processing vessel options can be as varied as the sauces themselves, with many design choices that will impact your product’s quality, consistency and production efficiency. To help you decide what’s best for your sauce processing operation, be sure to consider these factors:

Why Do We Design Tanks with Coil Jackets?

Have you ever wondered why Lee's tanks are designed with coil jackets? See how one of the most important innovations of Lee's 90-year history makes a key difference in throughput and consistency in every batch.

How to Make Sure the Kettle You Order is Actually the Kettle You Need

Much goes into building a high-performance processing vessel for a food, chemical or pharmaceutical manufacturing operation. Dozens of choices must be made about size, materials, mixing speeds, type of agitation, temperature, port locations, surface finishes and more. And each choice has an impact on how effectively the vessel performs in your environment. This blog article will guide your vessel design decision making and make sure you ask your process engineer the right questions.

5 Vessel Design Requirements for Optimizing Food Grade, Specialty and High-Performance Lubricant Manufacturing

Food-grade, specialty and high-performance lubricants, can pose mixing, temperature and safety challenges that require specialized vessel features and performance. To meet these processing challenges, manufacturers may be wise to emphasize five key characteristics in their processing vessels for optimal results. See the five key characteristics in our latest blog article.

Three Vessel Design Enhancements to Improve Your Throughput

Faster batch processing is a common goal for food processors. It’s often the impetus for adding more processing equipment. But improving throughput can involve much more than simply adding capacity. Depending on your objectives, optimizing your vessel design can dramatically reduce your batch processing time while also improving safety, product quality and product consistency. Here are three areas where optimizing your processing vessel can produce significant results.

Steam or Hot Water? Which Heating Source is Best for Your Operation?

Choosing a heat source is a key consideration for all food processing operations. For processors who use a jacketed kettle design, the choice comes down to steam versus hot water. But is one of them superior? And when would you choose to use one heat source over the other? Let’s consider some of the advantages of both steam and hot water while taking a look at some potential applications.

Why Surface Finish Grades are a Key Part of Your Production Vessel

The surface finish grade is a crucial but perhaps overlooked component of your production vessel. The surface finish affects more than the look of your vessel; it’s also critically important to how your vessel accomplishes its intended task — or whether it’s able to at all. A vessel’s surface finish will determine what products can be produced within that vessel. From pharmaceuticals to chemicals to food products, each industry has surface finish standards that must be met. And even beyond industry requirements, a vessel’s surface grade can have a big effect on how your product is produced.

The Importance of a Clear Manufacturing Quote for Your New Processing Vessel

Obtaining a proposal for equipment you intend to use in your processing operation is a critical part of your purchase process. Here are three key benefits of a clear, easy-to-understand manufacturing equipment quote.

Three Questions You Should Ask Your Processing Equipment Manufacturer

Preparing to buy a new piece of processing equipment can be a daunting process, but it doesn’t have to be. Knowing the right questions to ask before you buy can put you on the path to success.

Crucial Factors to Consider When Expanding Your Food Processing Operation

No matter the size of your current food processing operation, you may someday need to expand. If and when that day comes, you’ll have to address important questions regarding the expansion’s impact on your production.

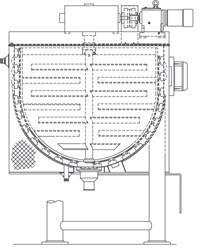

Three Ways Inclined Agitation Improves Operational Efficiency

Choosing the right kettle design is a key part of your food processing operation. When it comes to optimizing your production, there are two clear alternatives in the mixing and agitation area: horizontal ribbon blenders and hemispherical kettles with inclined agitation.

Five Questions to Ask When Buying a Used Kettle

Buying a used processing kettle can be a great option for expanding your operation or replacing older equipment. Used kettles and other vessels can often be available more quickly for lower prices than you’d see if you were buying new. But after weighing availability, price and basic design factors like shape, capacity and agitator type, there are other things you should weigh when deciding whether or not to buy a used kettle.

Use the 10X Rule to Guide Your Food Production Expansion

Your food product is taking off and you need to increase your production capacity to keep up. If that is your situation, you may be asking a fundamental question to determine your processing equipment needs: how much capacity can I get from each processing kettle without affecting my product’s quality or consistency?