Kettles

Lee Industries Styles

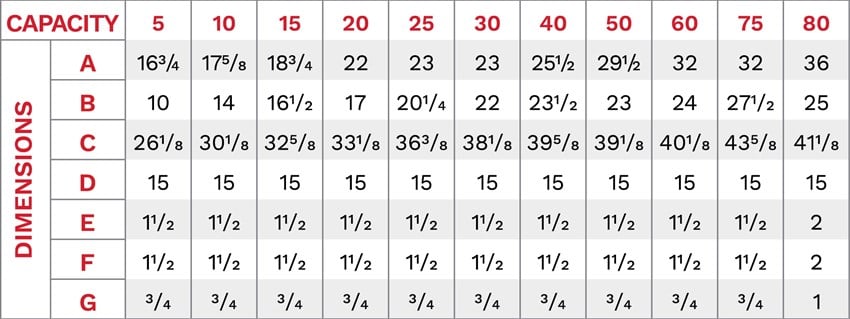

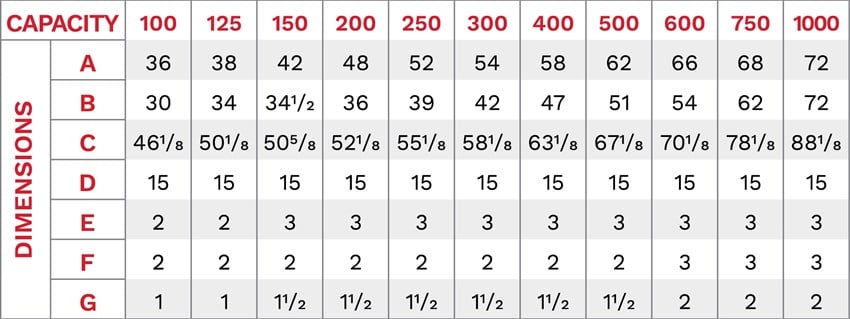

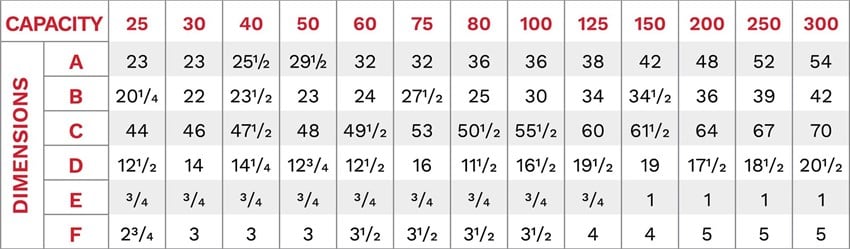

We’ve been designing kettles that meet all processing requirements for decades. Built to ASME specifications in various jacket styles and pressure ranges, they are available with a wide variety of features and accessories. They can be modified or custom built to your specifications, whether you need to accommodate pre-existing floor scales, doorways, room size, or other limitations. We can tailor our products to your facility and your specific process, including vacuum and pressure operation.

All Styles Feature:

- Traditional high-polished sanitary finish

- Sanitary flanged rims

- All stainless steel product contact parts

Outlet Features:

- Exclusive Lee designs permit shorter outlet fitting

- Sanitary Acme threaded or tri-clamp ferrule provided on stationary kettles

Support Features:

- Stainless steel pipe legs with fixed floor flanges

- Available on stationary and tilting kettles

Trunnion Style Features:

- Free-pouring spout

- Tilt handle on CD style

- Hydraulic tilting on CHD

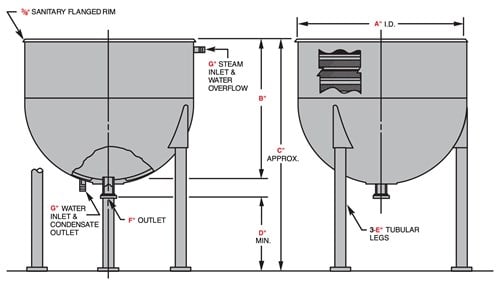

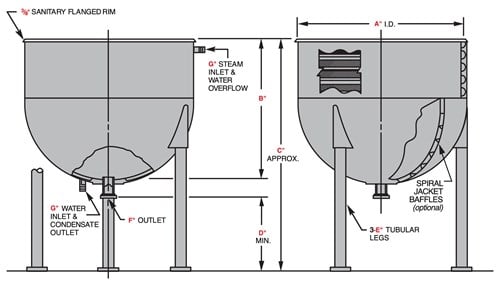

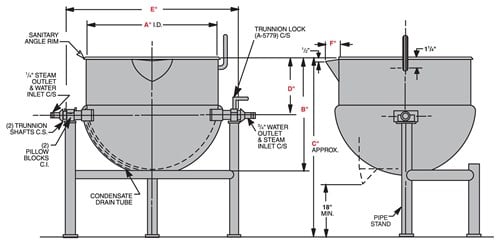

Style D

Style D - Super Jacket Stationary with Uniflow Coil Jacket

- Continuous coil automatically welded to vessel straight side for exceptional bond

- Hot or cold spots eliminated with Lee’s Uniflow coil jacket providing uniform thermal flow

- Optional spiral jacket provides directional flow of heating or cooling medium

Style CD – Super Jacket Trunnion Mounted with Manual Tilt

- Trunnion mounted and pouring lip for tilt-pouring

- Outlet or valve may be added to bottom for draining

- Positive latching meets federal safety standards

- Standard features

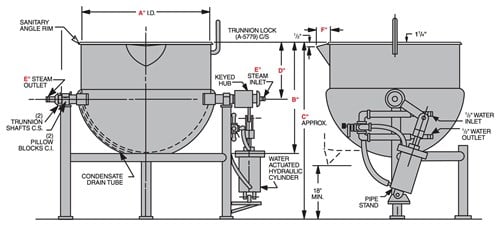

Style CHD – Super Jacket Trunnion Mounted with Hydraulic Cylinder

- Identical design to the manual tilt model

- Hydraulic titled trunnion kettles available in capacities ranging from 25 to 1,000 gallons

Options & Accessories

While the style you choose will have its own set of features, you also have the opportunity to choose from a few other options.

Instrumentation

Temperature recording and control can play a critical role in your processing technique. Our temperature sensing

or control instruments can ensure you yield the desired results in heat transfer vessels. We offer:

- A wide variety of temperature sensing control and recording instruments

- Probe-type sensors for open styles

- Stainless steel flush mounted sensors for scraper blade agitator installations

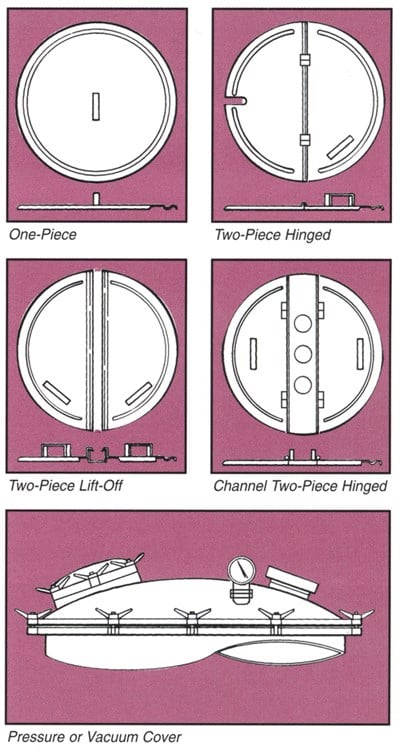

Covers

We offer various styles of sanitary covers for all types of Lee vessels.

- Two- or three-piece covers, either lift-off or hinged

- Furnished with special fittings or openings. if necessary

- Designed to include a vacuum/pressure style cover if required

Electropolishing and Finishing

We recognize the demand for high-quality, durable, ultra-sanitary finishes. We provide world-class mechanical finishes and can also provide electropolish finishes on all of our parts and products.