Tanks

If you're looking to store or process your product, our tanks are up for the job. They are made to the strictest industry standards and will meet or exceed your certification requirements. We serve a variety of industries, that make a variety of products. Whether you need to add a cover designed for pressure or vacuum applications, or a jacket for heating or cooling, they are designed to give you the best version of your product, in large batches. Interested in mixing a smaller batch? Consider a Lee kettle. Or, if your priority is heating and/or cooling, consider a Lee cooker / cooler.

Lee Industries Styles

Lee builds the tank that is right for the job. Our methods, processes, experienced team, modern production equipment and plant facilities work collectively to produce a full line to meet your specific needs. Lee Industries manufactures a wide variety of vessels and reactors, from jacketed ASME tanks to single-shell units all fabricated to customer specifications and processes.

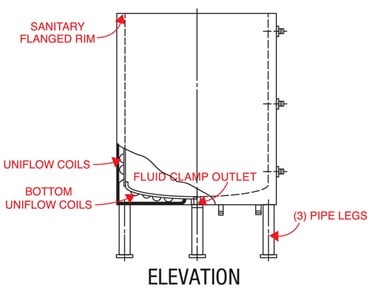

All Styles Feature:

- #4 finish inside and outside

- Sanitary flanged rims

- Various certifications such as ASME and USDA

Outlet Features:

- Exclusive Lee designs permit shorter outlet fitting

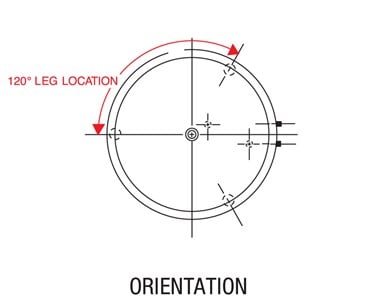

Support Features:

- Stainless steel pipe legs

Styles

- Pharmaceutical

- Bioreactors

- Heavy Duty processors

- Hold tanks

- Vaccine

- WFI

- Storage

- Mixing

- Food processing

- Chemical blending

- Vacuum/pressure

Customization

Every part is customizable - from the cover to the feet. We've included an overview of each of the options below.

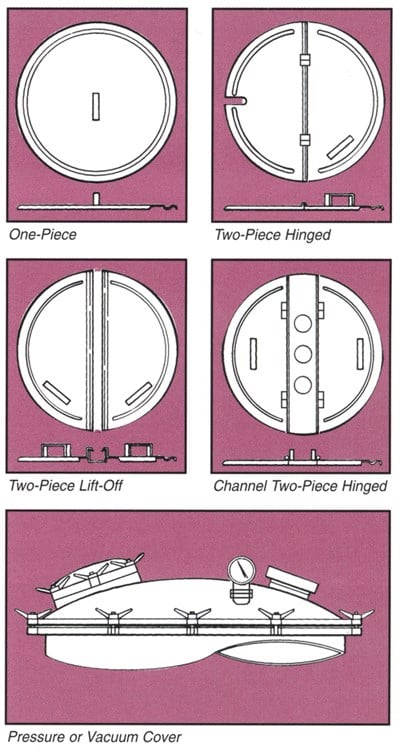

Covers

Covers designed for pressure or vacuum applications are available for all Lee tanks. Choose from:

- Bolt-on type

- Quick-release style

- Welded (to the cylinder)

- One-piece

- Hinged

View Cover Sketches

Cylinders

Pitched Bottom

Dished Bottom

Cone Bottom

Bottoms

- Pitched offers excellent drainage for liquids and places the outlet on a horizontal axis.

- Dished offers center draining for more viscous products. Reverse dished bottoms are also available.

- Cone is ideal for viscous or semi-solid materials. The standard cone bottom angle is 120º, but can be varied to suit process or product requirements.

Outlets

- I.P.S

- Sanitary Acme thread

- ASA flange

- Sanitary quick clamp

Lee manufactures diaphragm and flush ball outlet valves which are ideal outlets.

Options & Accessories

While the style you choose will have its own set of features, you also have the opportunity to choose from a few other options.Manways

Standard manholes are available for either head or cylinder mounting.

Electropolishing and Finishing

We recognize the demand for high-quality, durable, ultra-sanitary finishes. We provide world-class mechanical finishes and can also provide electropolish finishes on all of our parts and products.

Jackets

Two different heat transfer jacket options, open or Uniflow coil style, are available.